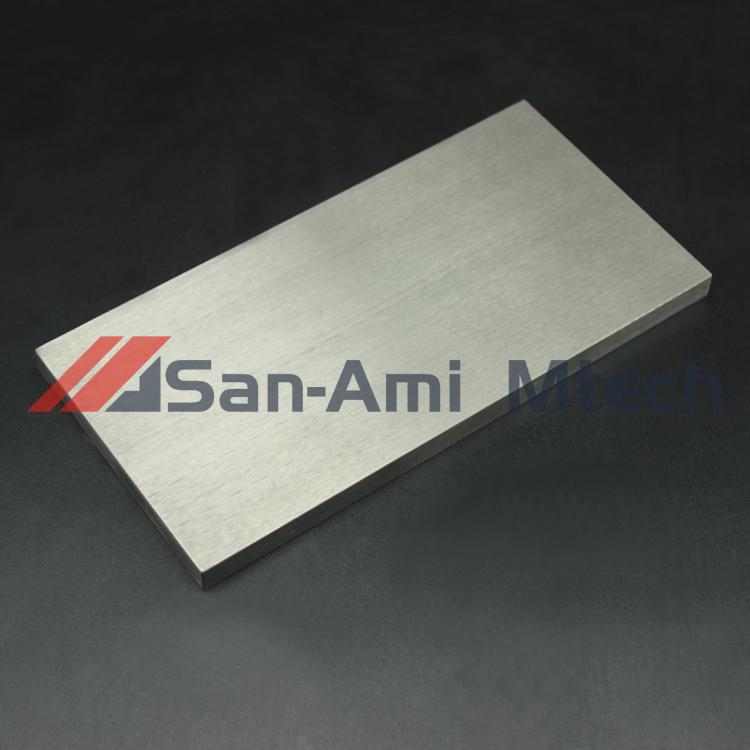

Description

Silicon carbide heating rod

The silicon carbide heating rod, also known as the Silicon Carbide (SiC) rod, is an important non-metallic high-temperature electric heating element.

Raw Materials: The Silicon Carbide (SiC) rod is primarily made from high-purity green hexagonal silicon carbide (Silicon Carbide (SiC)).

Manufacturing Process: The raw materials are processed into blanks with a specific material ratio and then sintered at 2200°C through a recrystallization process to form rod-shaped or tubular elements.

Typical application

Silicon Carbide (SiC) heating rods are widely used in various high-temperature applications, including but not limited to:

·Electronics

·Magnetic materials

·Powder metallurgy

·Ceramics

·Glass

·Semiconductors

·Analytical chemistry

· Scientific research

Silicon Carbide (SiC) heating rods are used as electric heating elements in various heating equipment such as tunnel kilns, roller kilns, glass furnaces, vacuum furnaces, muffle furnaces, smelting furnaces, and more.

Advantage

High-temperature Resistance:

The Silicon Carbide (SiC) rod exhibits excellent high-temperature resistance, with a normal operating temperature of up to 1450°C and continuous operation for thousands of hours.

Oxidation and Corrosion Resistance:

The Silicon Carbide (SiC) rod has good oxidation and corrosion resistance.

Quick Heating and Long Life:

The Silicon Carbide (SiC) rod heats up rapidly and has a long service life.

Small Deformation at High Temperatures:

The Silicon Carbide (SiC) rod exhibits minimal deformation at high temperatures, maintaining good stability.

Easy Installation and Maintenance:

The Silicon Carbide (SiC) rod is relatively easy to install and maintain.